This is my first attempt at creating a mold for the wheel. Below are a few progress pictures as I went along.

I used Tap Plastic Polyurethane mold material for this project.

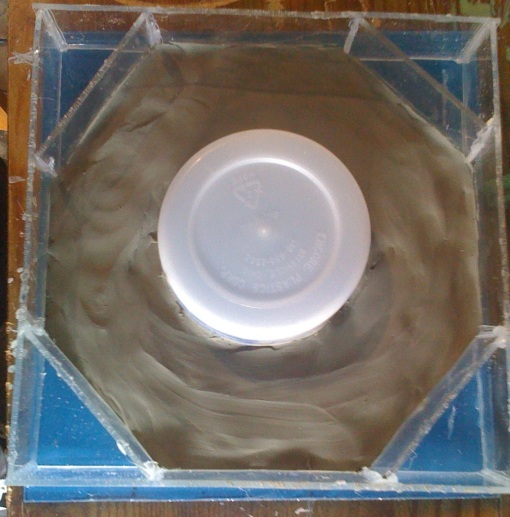

The first step was creating the mold frame out of plexi, I used a glue gun to secure the panels together, and a really thin bead of glue to secure it to the base panel. This will allow me to remove the mold piece to flip it.

I added clay to be able to depress the wheel so I can create the mold half.

To calculate how much mold material I will need, I used rice to estimate the volume. This was the way Tap Plastic suggested doing it, not the best way in my opinion. The rice sticks to the clay and takes forever to remove!

The final step was to pour the mold material. This will need to set up for 48 hours.

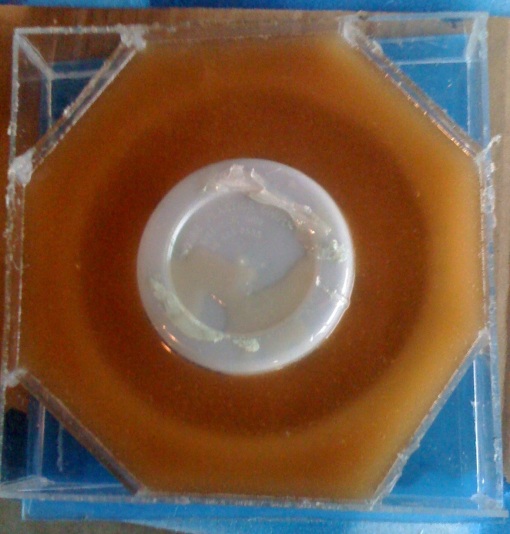

48 hours later I flipped the mold and here is the clay bottom.

Even with the use of mold release the clay still stuck to the polyurethane. The bits left that you see in the picture were removed before the pour of the second mold half. Notice the 5 nubs sticking up that act as “keys” to match the two halfs together. Also note the three small “pour spouts” that will allow me to pour in my casting material once the two halfs are together. Another 24 hours and I will be able to make my first tire.